Situation: Decommissioning prior to demolition of old high school; nearly all furnishings replaced and made surplus.

Material Composition: Complete school furnishings. Desks, chairs, work & conference tables, administrative office furniture, kitchen & cafeteria furnishings, library furniture.

Quantity: Approximately 4,200 pieces; Twenty-three shipping containers

Setting: Suburban school; Single exit, small loading dock at much less than truck height; Surplus concentrated in gym & pool area, some scattered throughout; three days to complete the project.

Click here for a printable PDF of this case study.

OVERVIEW

The City of Newton opened a new high school in 2010. Decommissioning the old school, the City was left with thousands of pieces of surplus. As much as possible was reused or donated locally, but there remained more than 4,000 items that could not be placed locally.

The City of Newton went through competitive bidding to identify the most cost-effective solution to handle the surplus. IRN’s surplus reuse program was bid directly against discard and recycling alternatives, and was the city’s least cost option by a significant margin.

Because of delays in the bid process, the project needed to be completed in three days. IRN loaded 23 shipping and storage trailers with some 4,200 pieces, sending more than 150 tons for reuse, plus another 37 tons of damaged, unusable items for recycling in local markets.

SETTING

Newton is a near-suburban town less than ten miles from downtown Boston. The high school is located in a residential neighborhood, hampering access for large vehicles. A two-vehicle loading dock was available, but dock height was less than two feet, requiring all materials to be ramped into trailers.

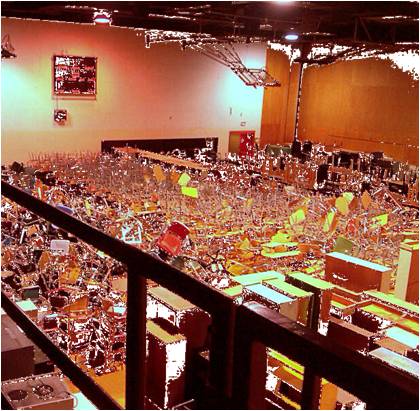

About 80% of surplus items were packed into the gymnasium and pool area. The balance were scattered throughout the structure.

SURPLUS COMPOSITION

AV equipment (87); Lab benches (170); Bookcases (285); Storage cabinets (144); Study carrels (48); Wheeled carts (18); Chairs (1226); Tablet armchairs (695); Couches (37); Partition components (32); Desks (359); File cabinets (147); Gym equipment (20); Kitchen equipment (33); Locker units (40); Shelving (56); Stools (87); Tables (518); Other (255)

KEY CONCERNS

Duration: Because of delays in the procurement process, the project needed to be completed in only three days.

Material Composition: In addition to usable surplus, there were hundreds of items too damaged to reuse, so two dumpsters needed to be available at all times, one for items recyclable as metal, the second for items recycled as mixed debris.

Material Handling: Although most of the surplus was consolidated in the gym and pool area, it was jumbled and stacked several pieces high, and there were long carries and fall concerns with surplus on the pool apron.

Loading Facilities: Every one of 4,000+ pieces had to come through just two double doors onto a 10’x20’ loading dock. Dock height was only 22”, so all surplus had to be pushed up ramps into shipping trailers.

Through our status as an approved vendor under Mass. State Contract FAC-57, IRN scheduled a 15-man crew on each of three days. Seven trailers were loaded on Day 1, nine trailers on Day 2, and seven trailers on Day 3. With such short lead time, IRN divided the surplus among 18 shipping containers that were loaded directly for overseas destinations, plus five storage trailers that were sent to a local yard to be subsequently unloaded and repacked into containers for overseas shipment.

At any given time there were between one and three trailers on the loading dock, with an IRN project manager directing surplus into the correct trailer as movers took it from the building. In intervals when there were only one or two trailers at the dock, IRN directed the crew to continue moving and stage furniture on or as close to the dock as possible, so the next trailer could be loaded quickly and efficiently when it arrived.

IRN’s onsite manager also assured that items too damaged for reuse were disposed of in the appropriate roll-off container (metal or mixed debris).

DESTINATION

About 2,000 pieces, or 45% of the Newton North surplus, were shipped to Food for the Poor’s central Caribbean warehouse in Jamaica. Although FFTP ships from Jamaica throughout the Caribbean Basin, most of the Newton North surplus will ultimately be shipped to Haiti for reconstruction after the January 2010 earthquake. Four loads or approximately 700 pieces were shipped to the Fundacion Nuevos Horizontes for community building programs in El Salvador, and four loads were provided to the American Nicaraguan Foundation, whose mission is to address a deficit of some 400,000 to 500,000 homes needed to alleviate the effects of natural disasters and long-term poverty. Another 37 tons of damaged or unusable items were recycled locally for metal and/or wood content.

COST

Disposition Cost: This was a public competitively bid project, so direct comparison against disposal costs is possible. IRN’s bid cost was approximately 38% less than the next lowest competing bid for recycling and/or disposal.